industrial applications

Monitor the health of bearings and gearboxes of critical plants successfully. Improve uptime and capacity.

Industrial applications: our offering

| Stable operations: thanks to 24/7 continuous condition monitoring and condition prediction | |

| Maximum component lifespan: utilization of the remaining lifespan thanks to artificial intelligence (AI) | |

| Efficient service: thanks to knowledge of the defective component, on-site troubleshooting is no longer necessary | |

| Simple and safe operation: thanks to the intuitive and user-friendly interface | |

| Integration into your system: by displaying analysis results, e.g. trends in your control system or PPS | |

| Highest data security: autonomous, passive AI system, independent of control system and IT |

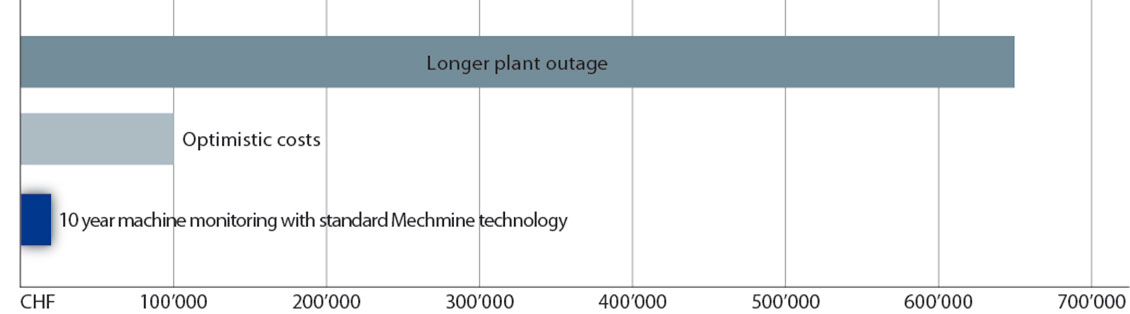

Costs - benefits: amortization of the Mechmine solution in 4 to 24 months

In a pharmaceutical production site, the clean rooms in the laboratory building and the production hall are fed by two fans. If the laboratory can no longer work due to a ventilation failure, the associated production must be stopped. A production interruption causes costs in a six-digit range after a short time. Critical systems are monitored in order to reduce the spare part warehouse for the more than 100 different types of motors and pumps installed on site. Using Mechmine vibration monitoring, the condition of both fans can be determined and trends can be derived. This means that spare parts can be ordered in good time and repairs can be planned if necessary.

Mechmine technology

Mechmine increases your system availability by changing from condition monitoring to predictive maintenance. Determine the time of maintenance and repair yourself. Successfully monitoring bearings or gears in critical machines or your products in the field with dedicated IoT solutions. Mechmine offers a secure retrofit turnkey solution - access from anywhere, anytime and comprehensible to everybody.

Continuous monitoring & forecasting, 24/7

- From condition monitoring to predictive maintenance

- Increases plant availability

- Failure prediction in «just-in time» supply chains

- Utilisation of remaining useful life of components

- Turnkey solution, everything from one source

Highest data quality & data analysis performance

- Optimized hardware for slow-rotating motors (RPM<600)

- Optimized hardware for high-RPM shafts (RPM>20’000)

- Optimized algorithms for gears

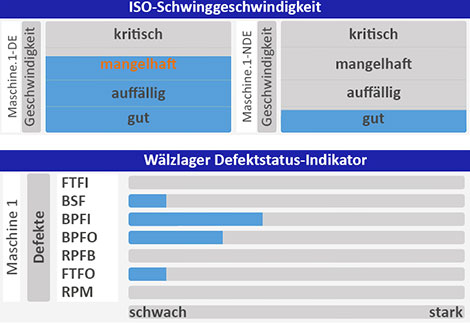

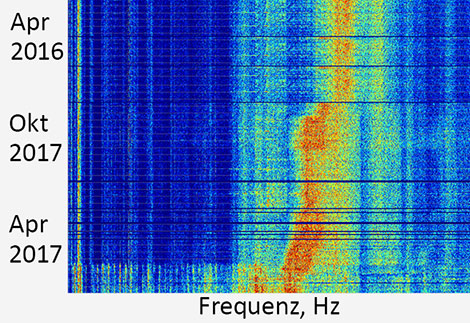

- Early detection and warning of upcoming defects and affected component

Intuitive user interface

- Appropriate and user-tailored visualization through several levels

- Traffic lights – trends – details

- Data and trends can be displayed in any control system

Improved efficiency of customer service

- Technicians know the defect before they arrive at the customer's premises

References and examples

-

Drives and gearboxes, especially suitable for very slow turning machines

-

Monitoring of heat pumps or residential water pumps with IoT solutions

-

Bearings in motors of hydraulic pumps or transport systems like container cranes

-

Gears and bearings in large industrial plants

-

Centrifuges and pumps in water treatment plants or utilities

Exemplary illustrations

Trend displays in the control system / QA

Trend displays in the control system / QA Dashboards

Dashboards Early detection of anomalies

Early detection of anomalies