Bearing problems can cause unplanned machine switch-off

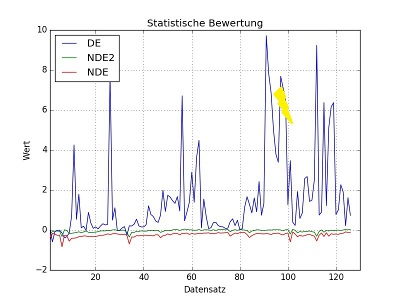

We could witness vibration problems causing an emergency machine stop during our data gathering pilot trial. The following picture shows a statistical metric we use for a 3MW generator with three bearings, one at the DE and two at the NDE side. The x-axis shows a time index and the y-axis denotes f(x) of the statistical metric used.

The arrow indicates the time of the machine's power-off. Further detailed data analysis revealed a typical bearing outer-ring defect pattern.